Introduction to Capillary Glass Fabrication Tools

Product Summary

Needle micropipette fabrication devices include instruments intended to pull, bevel, or forge various types and styles of glass micropipette needles for ICSI, IVF, transgenics, patch recording or other similar procedures involving the use of micropipettes in electrophysiological recording, microinjection, and microperfusion techniques.

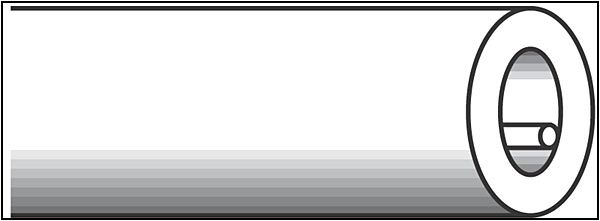

The first step in the process involves the initial fabrication of the micropipette itself using either single or multibarrel capillary tubing. This tubing typically ranges in size from between 1 and 2 mm OD and is usually made from borosilicate glass although other materials such as aluminosilicate or quartz are also used in some applications.

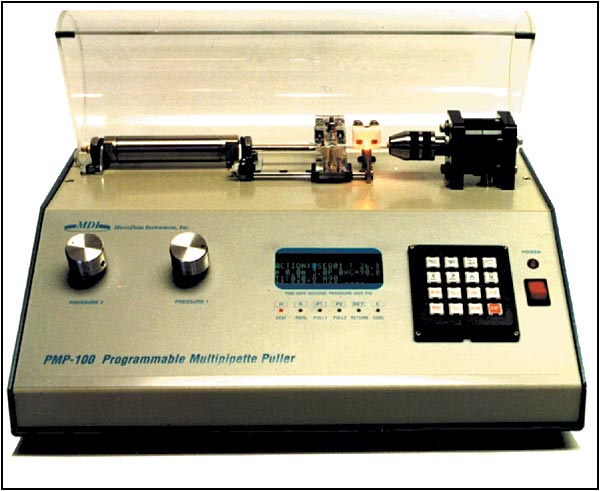

The capillary tubing is then placed in a micropipette puller where a point on the capillary tubing is brought to its softening point through the use of a heating device such as an electrical filament, laser or gas flame. Once the capillary tubings softening point temperature is reached, a mechanical parallel pulling force is applied to each end of the capillary tube and it is pulled to the desired tip diameter and profile. Depending on a number of preset variables such as capillary material type, temperature, filament type and pulling force, numerous types of tip profiles and tip diameters can be fabricated. Using this technique tip sizes as small as 0.02 µm can be achieved. Pipette pullers can range in complexity from a simplistic spring/counter weight mechanical puller to highly sophisticated programmable microprocessor controlled pullers.

Once a micropipette has been pulled down to the desired tip diameter and taper, it can either be used in its original form or be put through additional processes. These processes are designed to change tip diameter, tip bevel, tip geometry, bending to various angles or to add (fuse) additional segments. To alter (increase) the tip diameter or to apply a bevel to the micropipette the tip is subjected to a controlled micro grinding process through the use of a microbeveller. Microbeveller technology ranges from basic systems using wet alumina slurry on a rotating mirrored lapping disk, to sophisticated integrated optical-mechanical diamond based lapping wheel devices.

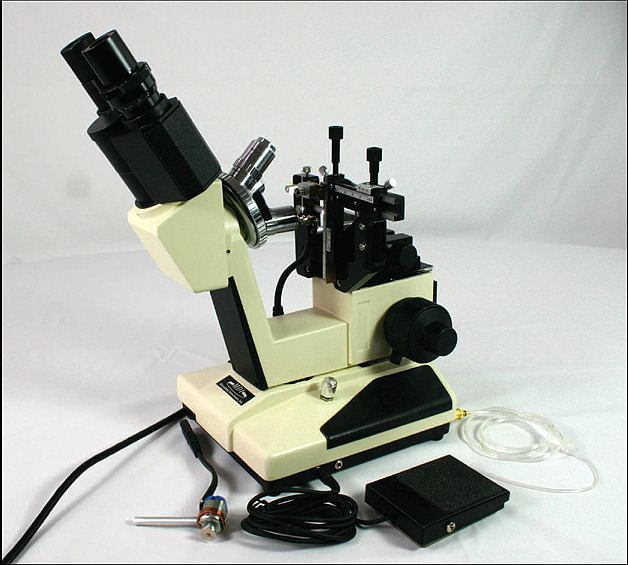

To reshape the pipette or to fuse the tip into a different geometry, a microforge system is used. A microforge uses a heating element, microscope, illumination, micromanipulators and microtools to change the shape of or contact fuse other elements to the micropipette pipette by heating certain sections of the micropipette to either soften (for bending) or melting (fusing) the micropipette. Some types of microforges can also fabricate metal and glass microtools.

Customers from Europe and Australia can use the Multi Channel Systems - Online Shop to order Warner products or create quotes.

| Order No. | Model No. | Product Description | USA Price | Order |

|---|